Development of predictive methods for formulation and developability studies

Despite the increasing availability of monoclonal antibody (mAb) drugs and their proven success in treatment of cancer, multiple sclerosis, asthma, rheumatoid arthritis, atopic dermatitis, and many other diseases, often with significantly improved outcome compared to the small-molecule therapeutics, the early identification of the mAb candidate molecules with desirable manufacturability, stability and delivery attributes remains a big challenge. Existing developability assessments for protein drug candidates vary in different industrial settings and depend highly on the quality and reliability of experimental methods being used to predict the stability of the candidate in formulation, manufacturing, packaging, and other stages. Common to all current assessments, however, is that they are limited in their capacity to predict the role that protein molecule characteristics and its formulation play in developability.

Currently, there is a critical need for experimental predictive methods that can quantify the relevant characteristics of biological molecules in formulations and in development pipelines. In the absence of such predictive methods, the potential to decrease the early, unwarranted removal of therapeutically promising protein drug candidates from development pipelines will remain limited. It is our aim in this area of research to build a scientific understanding and an experimental toolbox that improve developability assessments and formulation studies of biologics to ensure that the available data used for prediction are right-for-purpose, reliable and validated to perform.

Handling and manufacturing processes for protein pharmaceuticals

Development, manufacturing, supply and administration of protein pharmaceuticals is challenging and requires overcoming various hurdles such as issues with the purity of the protein product. The safety and efficacy of protein pharmaceuticals depend sensitively on their purity. Impurities in marketed protein pharmaceuticals may be present due to limitations in manufacturing processes or may also be a result of degradation processes occurring not only during manufacturing, but also during long-term storage of the bulk drug substance and/or final drug product (DP) as well as post-manufacturing handling steps. Impurities within therapeutic protein products can cause severe adverse drug reactions in patients, that may be acute, as is the case for infusion-induced anaphylaxis and pseudo-allergy responses, which may even result in patient death, or long-term, like unwanted immunogenicity. It is the aim of this research area to understand the effect of common handling/mishandling processes in manufacturing, supply and administration of biopharmaceuticals, to identify risks and to provide solutions. For instance, we have previously uncovered the effects of disturbing the interfaces in generation of protein aggregates and impurities in mixing processes. Our study has resulted in optimization of stirring process steps and overall improvement of manufacturing processes for biopharmaceuticals. Our lab is a member of the Protein Handling focus group within the American Association of Pharmaceutical Scientists and together with other academic and industrial partners we aim for improving the safety and efficacy of biopharmaceuticals by enhancing the understanding of the impact of handling processes and ways to overcome those.

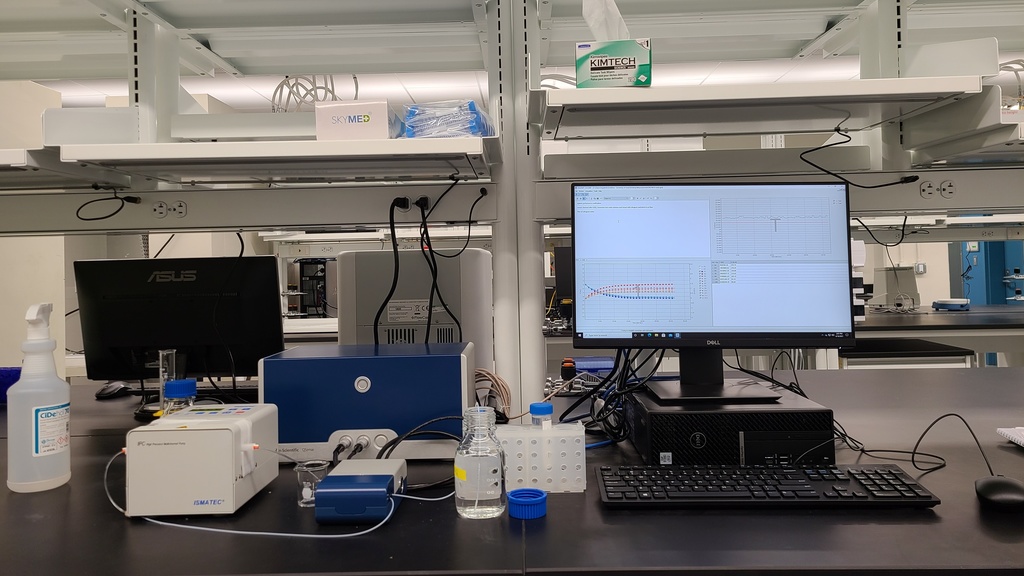

Development and optimization of novel analytics for characterization of biopharmaceuticals

Being a relatively a young branch of science and having the challenges of dealing with delicate protein molecules that have complex structure and function, the field of biopharmaceuticals has been in search of novel analytics that can address many of the current questions and that can improve the development processes of much-needed therapeutics. Our research in this area looks at novel methods and also new modes of use for conventional methods to gain a good understanding of protein molecules, their aggregation and interaction with interfaces. By way of example, we have shown how a suspended microchannel resonator can be used to study the interaction of proteins with nanoparticles. We work on developing and improving novel characterization methods that have positive impact on development, manufacturing and regulatory aspects of biopharmaceuticals.